INCON Optimizer 3

INCON Optimizer 3

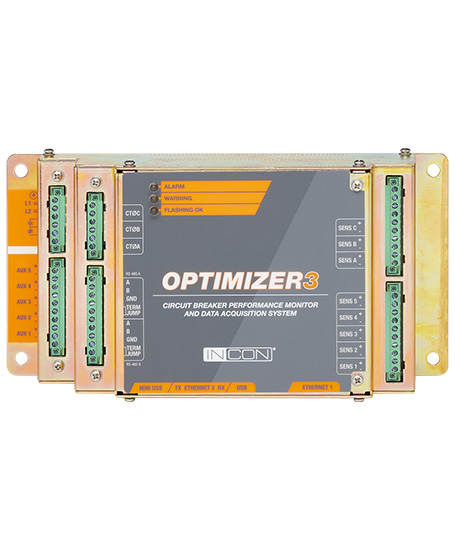

The INCON® Optimizer3 Circuit Breaker Monitor delivers advanced automated reporting of all critical circuit breaker diagnostics to ensure uptime and facilitate predictive maintenance. The Optimizer3 is ideal for high-voltage, live or dead-tank, oil, vacuum or gas circuit breakers.

With early detection of circuit breaker deficiencies and automated system performance evaluation, the Optimizer3 Circuit Breaker Monitor provides utilities with the tools to help improve efficiency, extend equipment service life, and enhance reliability of their systems.

With 8 sensor inputs, 5 timing inputs, and an onboard ambient temperature sensor and supply voltage monitor, the Optimzer3 and its array of sensors deliver a complete diagnostics report of a circuit breaker’s performance. Utility technicians are empowered with the data to repair a small issue before it causes a substantial failure that may require equipment replacement or even an entire overhaul of a high-cost asset.

VOLTAGE & CURRENT MONITORING

Real-time voltage and current are measured with an array of high-accuracy, loop-powered voltage and current transducers. Applications include motor current, station battery voltage, heater current, and compressor run-time.

SF6 GAS MONITORING

SF6 gas density, pressure, and dew point sensors and fill point adapters aid in the mandatory compliance reporting required by the EPA, resources boards, and other regulatory agencies by monitoring for SF6 gas leaks and related indicators and automatically reporting any fugitive emissions.

TANK HEATER MONITORING

The Optimizer3 monitors the tank heater’s supply current using a universal power status monitor. If one or more of the heater elements fails, the Optimizer3 will assert a heater alarm.

|

|

|

|

|

|

With 8 sensor inputs, 5 timing inputs, and an onboard ambient temperature sensor and supply voltage monitor, the Optimizer3 Circuit Breaker Monitor and its array of sensors deliver a complete diagnostics report of a circuit breaker’s performance. Click on each breaker cabinet component to see how.

The web-based interface allows users to securely connect directly to the Optimizer3 monitoring and alarm data from any web-enabled device without having to host anything on a server.

DATA COMMUNICATION

Performance data is delivered through standard network communication protocols to maintenance, reliability, and environmental protection stakeholders with role-based access and permissions.

SETUP & CONFIGURATION

Remotely setup and program, clear and reset alarms, install firmware upgrades. Personnel can also save, download and copy configurations between breakers.

REPORTING

Circuit breaker performance and SF6 gas compliance reports for regulatory agencies can be easily generated and exports in CSV format.

ONCE THE PRODUCT SHIPS, WE'RE JUST GETTING STARTED

The Franklin Electric Grid Solution Technical and Field Support Teams are here to assist with training, installation, and support. Our Field team will come to your site for training or installation supervision and our Support Center staff is available to assist with troubleshooting, warranty processing, and software installation support.

Components & Dimensions

1. Power input & relay output

2. CT inputs

3. Timing inputs

4. RS-485 ports

5. Digital/analog sensor inputs

6. Analog sensor inputs

7. Status LEDs

8. Mini USB port5678

9. Ambient temperature sensor

10. Fiber-optic port (optional)

11. USB 2.0 port

12. Ethernet port

13. Vents

14. Mounting holes

Specifications

Circuit Breaker Monitoring Capabilities

- Breaker State (Open/Closed)

- Breaker Timing

- Opening & Closing Time (Latch Time)

- Opening & Closing Travel Time

- Arc Time

- Interrupting Time

- Opening & Closing Travel Velocity

- Operations Count

- Fault-Interrupt Count

- Non-Fault-Interrupt Count

- Days Since Last Operation

- Trip & Close Coil Circuit Integrity

- Charging Motor Current Draw & Run Time

- Contact Wear & Restrike Detection

Circuit Breaker Monitoring Reporting

- 2-Hour Current Log (5000 Records – FIFO)

- Min., Max., & Average Current

- Event History (5000 Records – FIFO)

- Opening Coil (1 or 2)

- Timing Measurements

- Opening & Closing Velocity

- Peak Fault Current

- Alarm Status for Each Operation

- Contact Wear for Each Operation

- Accumulated Contact Wear

SF6 Gas Monitoring Capabilities

- Gas Density

- Gas Pressure

- Gas Temperature

- Leakage Trend & Confidence Level

- Forecasts Days until Low Gas Alarm

SF6 Gas Monitoring Reporting

- Daily Average (750 Records – FIFO)

- Pressure, density, temperature & SF6 mass

- 2-Hour History Log (5000 Records – FIFO)

- Pressure, density, temperature

Sensor Types Supported

- SF6 Gas Density, Temperature, Pressure

- SF6 Gas Dew Point

- Generic AC/DC Voltage & Current

- Generic (Hydraulic, Air) Pressure

- Generic Temperature

- Tank Heaters (UPSM-241)

- Analog: 4-20mA (Loop-Powered)

- Digital: Frequency/Pulse-Width Modulated

Immunity and Emissions Certification

- CISPR 16-2-1 (Conducted Emissions)

- CISPR 16-2-3 (Radiated Emissions)

- IEC61000-4-2 (ESD)

- IEC61000-4-3 (Radiated RF)

- IEC61000-4-4 (EFT)

- IEC61000-4-5 (Surge)

- IEC61000-4-6 (Conducted RF)

- IEC 61000-4-11 (Voltage Dips & Interrupts)

- IEC 61000-4-12 (Damped Osc. Wave, Power Ports)

- FCC Part 15, Subpart B; ICES-003 (Emissions)

Specifications

| Environmental | Operating Temperature: -40 to 65° C Storage Temperature: -40 to 65° C Humidity: 0 to 95% Non-condensing |

| Communications | RS-485 Full/Half Duplex Ethernet Fiber-optic (OM3D-F Model Only) |

| Relay Output | Dry Contact; 1 ea. Form C |

| Relay Contact Rating | N.O: 5 Amps @ 250 VAC or 3 Amps @30 VDC N.C: 2 Amps @ 250 VAC or 1 Amp @ 30 VDC |

| Relay Contact Fuses | 3.15 A Slow-Blow |

| Power Supply Input Voltage | 110-250 VDC / 90-264 VAC, 50 / 60 Hz |

| Power Consumption | 60VA Maximum |

| Power Supply Input Fuses | 3.15 A Slow-Blow |

| Aux Input Voltage | 0 to 48 - 250 VDC |

| Aux Input Fuses | ¼ A Fast-Blow |

| Aux Input Impedance | 540K Ohms |

| CT Pickup Coil Input Signal | 0 to 5 VAC |

| Input Sampling Rate | 32 Samples per line cycle |

| Sensor Signal | Analog: 4 to 20 mA Digital: Frequency & Pulse-Width Modulated |

| Sensor Power | 20 VDC @ 25mA Max |

| Analog Sensor Accuracy | +/-1% of Full-Scale Max, +/-0.5% Typ. |

| Dimensions | 280 mm L x 70 mm W x 143 mm H 11" L x 2¾" W x 5 5/8" H |

| Shipping Weight | 6 lbs. (2.25Kg) |

COMMUNICATION

The Optimizer3 functions as a web server itself, with no additional software required for communication. It is connected to a network via either a fiber optic, Ethernet or RS-485 connection to facilitate the transfer of data. The web-based interface allows users to securely connect directly to the Optimizer3 data from any web-enabled device without having to host anything on a server.

Remote Functions

- Setup

- Programming

- Alarm clearing

- Alarm resetting

- Firmware upgrades

Circuit Breaker Status

- Alarm status

- Date/time of last operation

- Operation number

- Real-time RMS current

Sensor Status

- SF6 gas compliance info

- Ambient temperature

- Supply voltage

- Sensor information

Setup & Configuration

- The completed configuration can be downloaded and saved as an XML file

- The configuration file can be edited with a word processor and uploaded to other Optimizer 3 units, enabling them to be quickly configured for breakers of the same type

Data Security

To accommodate the high level of importance power utilities place on security, the Optimizer3 employs a multitude of contemporary security methods to prevent unauthorized access to data including:

- Secure access via HTTPS port only

- Encrypted USB flash drive access

- 10-minute inactivity timeout

- No default passwords

- Generic feedback from failed logins

- Hidden password characters

- Successful third party vulnerability threat testing:

- San Diego Gas & Electric

- Lower Colorado River Authority

OPTIMIZER3 CIRCUIT BREAKER MONITORS

| Model | Description |

|---|---|

| OM3D-F | Optimizer3 circuit breaker monitor, density measurement-ready with fiber-optic communication port |

| OM-MMK | Optimizer3 magnetic mounting kit |

Magnetic Mounting Kit

- Non-drill, easy mounting to ferrous metal panels and enclosures

- NEMA cabinet rating is not compromised by having to drill

- All hardware included: (4) clip nuts, (4) screws, and (4) magnets

ACCESSORIES & REPLACEMENT PARTS

CURRENT TRANSFORMER PICKUP COILS

Current transformer pickup coils enable the Optimizer3 to measure real-time current flow in the bushing current transformer secondaries. The split-core design allows the pickup coils to be applied to secondaries of bushing current transformers without disassembling or disconnecting the cabling for fast and convenient installation. They are available in eight current ranges to accommodate all applications.

| Model | Description |

|---|---|

| CT-20 | Current transformer pickup coil, 20 Amps |

| CT-30 | Current transformer pickup coil, 30 Amps |

| CT-50 | Current transformer pickup coil, 50 Amps |

| CT-100 | Current transformer pickup coil, 100 Amps |

| CT-160 | Current transformer pickup coil, 160 Amps |

| CT-250 | Current transformer pickup coil, 250 Amps |

| CT-400 | Current transformer pickup coil, 400 Amps |

| CT-800 | Current transformer pickup coil, 800 Amps |

Specifications

- Current sensors are specifically designed for use with Optimizer CT input circuitry

- Includes 8' wire lead

- 30' leads available upon request

- Accuracy greater than 1%

SF6 GAS MONITORING

The Optimizer3 aids in the mandatory compliance reporting required by the EPA, resources boards, and other regulatory agencies by monitoring for SF6 gas leaks and related indicators and automatically reporting any fugitive emissions.

SF6 GAS DENSITY SENSOR

| Model | Description |

|---|---|

| DSCC | 1/2" NPT conduit fitting adapter |

| DSAP-20 | Digital SF6 gas density sensor, temperature & density, 20 ft cable |

Specifications

- Density range: 0 to 60 grams per liter (kg/m3) SF6

- Temperature range: -40 to 85 °C

- Mounting thread: Male 3/8" BSPP

- Seal: Neoprene O-Ring

- Density: 1.8% of full scale max.; 1.0% of full scale typ.

- Temperature accuracy: +/- 1°C at ambient temperature +/- 3°C at -40 to 85 °C

- Output signal: Analog (4-20mA)

- Supply voltage: 10 to 20 Volts DC

- Electrical connections: 2-wire

- Operating temperature -40 to 70 °C

- Operating pressure -1 to 15 Bar

SF6 GAS PRESSURE SENSOR

The SF6 gas pressure sensor measures the temperature-compensated pressure of SF6 gas. The temperature and the compensated pressure measurements are digitally transmitted over a two-wire, power-line-carrier interface.

| Model | Description |

|---|---|

| PSDP | Digital SF6 gas pressure sensor, temp & pressure, 5 meter cable |

| OM-SC5 | 5 meter cable with 90 degree connector |

Specifications

- Pressure range: 0 to 9 Bar Abs at 20 °C compensated

- Temperature range: -40 to 85 °C

- Mounting thread: Male 3/8" BSPP

- Seal: Neoprene O-Ring

- Pressure accuracy: +/- 1% of full scale range at 85 °C +/- 2.2% of full scale range at -40 to 85 °C

- Temperature accuracy: +/- 3°C

- Output signal: Digital (frequency & pulse-width modulated)

- Supply voltage: 15 to 30 Volts DC

- Electrical connections: 2-wire

- Operating temperature -25 to 80 °C

- Operating pressure: 0 to 16 Bar absolute

SF6 GAS DEW POINT TEMPERATURE SENSOR

The SF6 gas dew point sensor measures the moisture content of SF6 gas. This solid-state sensor converts the measured dew point temperature to a milliamp analog signal.

| Model | Description |

|---|---|

| OM-DPS | Analog SF6 gas dew point temperature sensor, 5 meter cable |

| OM-SC5 | 5 meter cable with 90 degree connector |

Specifications

- Dew point: -60 to 20 °C

- Mounting thread: Male 3/8" BSPP

- Seal: Neoprene O-Ring

- Accuracy: +/-2 °C

- Output signal: 4-20 milliamp DC

- Supply voltage: 10 to 32 Volts DC

- Electrical connections: 2-wire

- Operating temperature -50 to 60 °C

SF6 GAS SENSOR PIPE FITTINGS

SF6 gas sensors can be installed directly into the ¼ pipe feeding the circuit breaker's pressure gauge using SF6 gas sensor pipe fittings. All gas connections must be checked for leaks if this method is used.

| Model | Description |

|---|---|

| OM-SAM | SF6 gas sensor pipe fitting for (1) sensor, Mitsubishi circuit breakers only |

| OM-SAM2 | SF6 gas sensor pipe fitting for (2) sensors, Mitsubishi circuit breakers only |

| OM-SAA1 | SF6 gas sensor pipe fitting for first sensor, ABB circuit breakers only |

| OM-SAA2 | SF6 gas sensor pipe fitting for second sensor, ABB circuit breakers only |

-

For ABB circuit breakers, if two SF6 gas sensors are required, an OM-SAA2 must be installed in addition to the OM-SAA1.

Voltage & Current Monitoring

Real-time voltage and current is measured with an array of high-accuracy, loop-powered voltage and current transducers. Applications include motor current, station battery voltage, heater current, and compressor run-time.

AC CURRENT TRANSDUCER

The AC current transducer is a loop-powered, split-core current transducer for measuring 50/60Hz alternating current. This transducer accurately converts measured AC current to a 4-20 milliamp signal, which can be monitored by the Optimizer3.

| Model | Description |

|---|---|

| OM-ACCT | AC Current Transducer |

Specifications

- Selectable input current range: 0 - 10, 0 - 20, and 0 - 40 amps

- Power supply voltage: 12 - 30 volts DC

- Current accuracy: +/-2% from 10% to 100% of full scale

AC LOW-CURRENT TRANSDUCER

The AC low-current transducer is a loop-powered current transducer for measuring 50/60Hz alternating current. This transducer accurately converts measured AC current to a 4-20 milliamp signal, which can be monitored by the Optimizer3.

| Model | Description |

|---|---|

| OM-ACLCT | AC Low Current Transducer |

Specifications

- Selectable input current range: 0 - 2, 0 - 5 amps

- Power supply voltage: 15 - 40 volts DC

- Current accuracy:

- +/-2% of full scale in the low current range

- +/-1% of full scale in the high current range

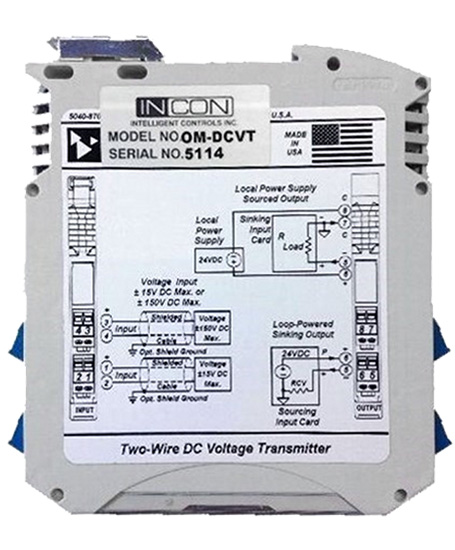

DC VOLTAGE TRANDUCER

The DC voltage transducer is a loop-powered voltage transducer which accurately converts measured DC voltage to a 4-20 milliamp signal, which can be monitored by the Optimizer3.

| Model | Description |

|---|---|

| OM-DCVT | DC Voltage Transducer |

Specifications

- Voltage range: 0 - 150 VDC

- Power supply voltage: 12 - 32 volts DC

- Voltage accuracy: +/-0.1% of full scale (+/-0.15 volts)

DC CURRENT TRANSDUCER

The DC current transducer is a loop-powered current transducer for measuring direct current. This transducer accurately converts measured direct current to a 4-20 milliamp signal, which can be monitored by the Optimizer3.

| Model | Description |

|---|---|

| OM-DCCT | DC Current Transducer |

Specifications

- Selectable current input range: 0 - 5, 0 - 10, 0 - 20 & 0 - 40 amps

- Power supply voltage: 8 - 28 volts DC

- Current accuracy: +/-0.5% of full scale

- Output circuit isolation: 1,000 volts DC

TEMPERATURE SENSOR

The temperature sensor is a loop-powered sensor which accurately converts the measured temperature to a 4-20 milliamp signal, which can be monitored by the Optimizer3.

| Model | Description |

|---|---|

| OM-TS | TempSense temperature sensor |

Specifications

- Power supply voltage: 12 - 30 volts DC

- Temperature accuracy: +/-2% of full scale

- Temperature range: -40 °C to 120 °C

TANK HEATER MONITORING

The Optimizer3 monitors the tank heater’s supply current using a Universal Power Status Monitor. Tank heaters are thermostatically controlled, so they do not run continuously. The power status monitor is wired in to the heater supply circuit and enables the current draw of the heaters to be monitored only when they are turned on. If one or more of the heater elements fails, the current draw will be too low and the Optimizer3 will assert a heater alarm.

UNIVERSAL POWER STATUS MONITOR

The universal power status monitor enables the Optimzer3 to monitor the AC current draw of circuit breaker tank heaters, cabinet heaters, or other high-powered electrical loads through its sensor input channels.

| Model | Description |

|---|---|

| UPSM-241 | Universal power status monitor with AC current transducer |

Universal Power Status Monitor Specifications

- Coil voltage: 195 - 330 VAC

- Fuse rating: 3 amps

- Dimensions: 5.1" (130 mm) L x 5.1" (130 mm) W x 4" (102 mm) H

AC Current Transducer Specifications

- Selectable input current range: 0 - 10, 0 - 20, and 0 - 40 amps

- Power supply voltage: 12 - 30 volts DC

- Current accuracy: +/-2% from 10% to 100% of full scale

TRIP CIRCUIT ISOLATION

The OM-TCI is a cost-effective method of complying with the Northeast Power Coordinating Council’s regulation requiring physical isolation of critical circuits in medium and high voltage environments. OM-TCI is used to physically isolate dual trip circuits when used in conjunction with the Optimizer Circuit Breaker Monitor (OM3D / OM3D-F).

Featured Downloads

Brochures

| Title | Type | Size | |

|---|---|---|---|

|

FEGRID-0007 Optimizer3 Circuit Breaker Monitor Brochure.pdf | 15.97 MB | |

|

FEGRID-0004 Optimizer3 Circuit Breaker Monitor Datasheet.pdf | 2.24 MB | |

|

FEGRID-0021 OM-TCI Trip Circuit Isolation Brochure.pdf | 5.26 MB | |

|

FEGRID-0053 Case Study - Navigating Redundancy Regulations.pdf | 1.2 MB | |

|

FEGRID-0052 Case Study - Remote Circuit Breaker Monitoring.pdf | 1.22 MB | |

|

FEGRID-0054 Case Study - Streamlining Grid Upgrades.pdf | 1.16 MB | |

|

FEGRID-0017 FE Grid Academy Certified Installer Training Brochure.pdf | 13.13 MB |

Manuals

| Title | Type | Size | |

|---|---|---|---|

|

000-1533 Optimizer3 User Guide.pdf | 6.42 MB | |

|

000-0321 Optimizer3 DNP3.0 Device Profile Document.pdf | 0.9 MB | |

|

FEGRID-0010 Optimizer3 Circuit Breaker Monitoring Project Guide.pdf | 0.56 MB | |

|

10000002055 Optimizer Trip Circuit Isolator Installation Guide.pdf | 3.33 MB | |

|

10000001561 OM-SAM2 Installation Guide.pdf | 2.92 MB | |

|

10000002554 OM-PS-10B Install Guide.pdf | 3.39 MB | |

|

10000012052 OM-RHS Install Guide.pdf | 1.04 MB | |

|

TBGS0424-01 OM3 1_11_2 Firmware Release Notes.pdf | 0.04 MB |

Software

| Title | Type | Size | |

|---|---|---|---|

|

OM3 Ver 1.11.2 Update Files.zip | ZIP | 87.2 MB |

|

OM2-1.1.5-USB_Upgrade.zip | ZIP | 9.88 MB |